Challenge

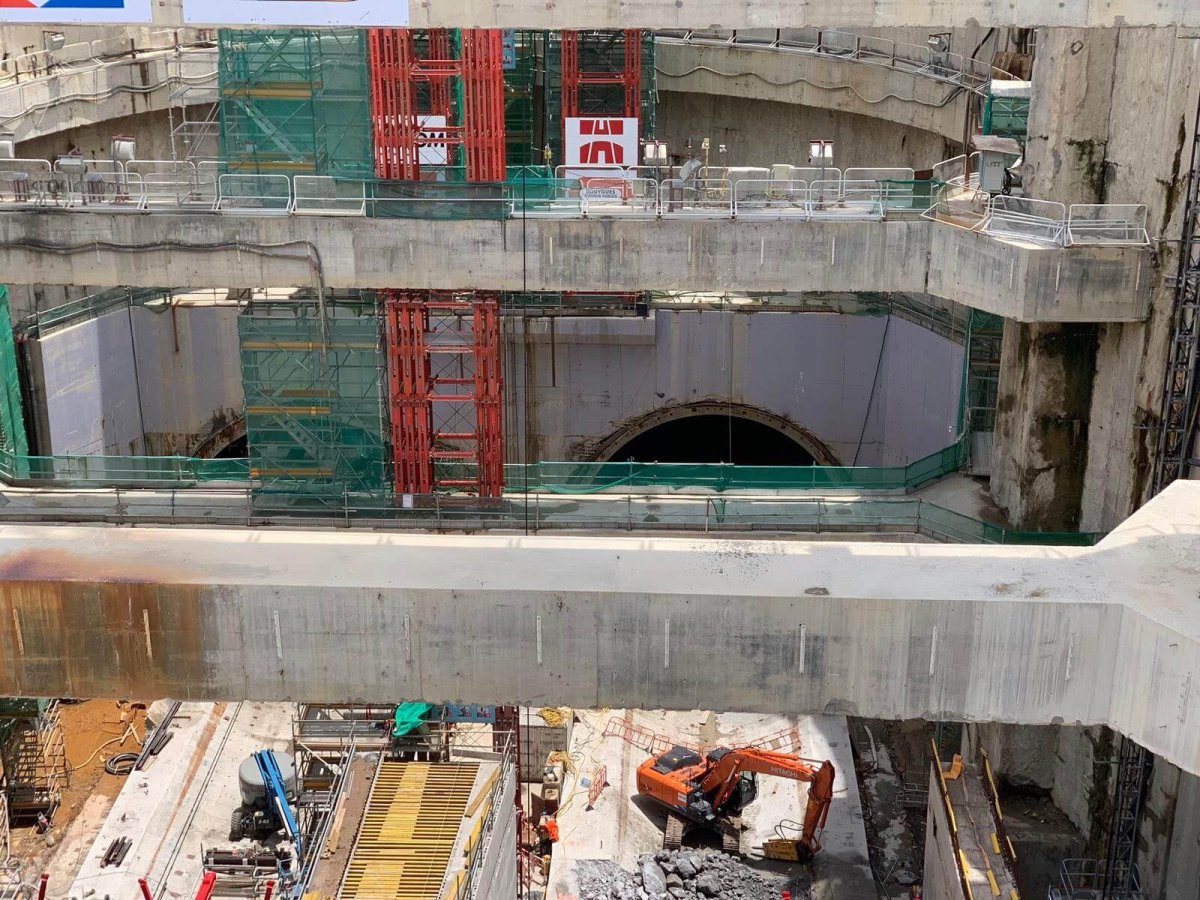

A major mining company in Peru wanted to measure displacement in the tunnel where its mineral conveyor belt is located. The company needed reliable readings of rock movement every six hours from the length of the approximately two-kilometre tunnel. The monitoring was complicated by potential signal interference from radio noise, magnetic fields, metals, pipes and other mine obstructions.

Geoteknik SAC, the Peruvian company that participated in the project’s monitoring, needed to source, install and oversee a monitoring solution that would provide consistent readings, ensuring a fail-safe data stream at the required intervals. A break in the flow would mean that the mining company would not have a clear, timely picture of rock movement underground, which could pose risks to tunnel stability and even worker safety.

Along with dependably sharing readings at the required interval from the tunnel, the monitoring solution also needed to be able to cover approximately 2 kilometres between the farthest node and the Gateway at the surface. And the client needed practical data-sharing software that would give its team members remote access at offices through its network.

Solution

Geoteknik chose the Ackcio Beam system for the reliability and stability of its automated wireless network, which has been tested and proven in some of the world’s most challenging underground sites, including cutting-edge mines.

This ability to go deeper without compromising the reliability of readings is due to Ackcio’s patented, long-range mesh communication protocol, which is engineered specifically to mitigate against data loss, even underground. It is supported by Ackcio’s background sync feature, which provides additional backup in the case of network disruptions. The data is stored in the Node’s onboard memory and automatically retransmitted when the network connection is re-established.

Geoteknik connected Ackcio VW Nodes (BEAM-VW-S8) to seven multipoint rod extensometers installed in the right and left axials of the tunnel along the mine’s ore conveyor belt. They also installed three Ackcio Repeater Nodes (BEAM-RN) to ensure full data coverage. The Ackcio Gateway (BEAM-GW) at the surface was connected to the mine’s ethernet, which shares the data with Ackcio’s Snape software.

The Ackcio solution proved to be a perfect fit for the challenging site.

Along with the easy installation of Ackcio’s Nodes and Gateway and the product’s friendly settings panel, the project saw perfect communication via mesh topology between Ackcio nodes.

The Geoteknik team reported a “very good experience,” citing Ackcio’s highly proactive and capable team, and supportive throughout the project. It will use Ackcio in the future when its client needs to monitor more points inside the tunnel.

Benefits

- Easy, seamless installation

- Friendly settings panel

- Automated wireless readings

- Integrated data-sharing software

Results

- Remote, real-time data access

- Reliable, stable readings from underground

- Increased mine, worker safety

- Improved risk management

Testimonial

Ackcio is a great brand, with instruments that are really capable of operating correctly in very adverse environments. It is very pleasant to work with Ackcio instruments.

– Robert Olivera, Project Engineer from Geoteknik SAC

Application

Monitoring an underground tunnel

Location

Peru

Products Used

Monitored Sensors

Multipoint rod extensometers

Measured Parameters

Displacement